Mineral Insulated Cable Heaters

Therm-x is an industry-leading manufacturer of Mineral Insulated (MI) Cable Heaters for process temperature or viscosity maintenance in many industries include semiconductor, aerospace, alternative energy, chemical, and petrochemical, etc.

Therm-x designs and manufactures MI cable heaters by using our own MI Heating Cables constructed of solid series resistance wires embedded in highly compacted mineral insulation. This capability allows Therm-x to configure and build custom-design MI Cable Heaters to meet a variety of demanding applications.

We provide MI Cable Heaters made with various sheath materials suitable for applications under general or corrosive conditions. Our heaters allow high-temperature and high-power density applications with a watt density up to 80 w/sq inch and maximum exposure up to 1300°F. The robust bulk cable construction coupled with precision welding technology ensures our MI cable heaters exhibit unmatched long-term stability of performance.

General Specifications (2 wire)

Cable ø | Min Wire ø | Max Wire ø | Max Length | Watts | Volts | Materials |

|---|---|---|---|---|---|---|

0.062" | 0.005" | 0.011" | 250 ft (76.2 m) | up to | 6 to 240V | Inconel 600 |

0.093" | 0.005" | 0.017" | 115 ft (35.5 m) | |||

0.125" | 0.006" | 0.023" | 120 ft (36.5 m) | |||

0.188" | 0.006" | 0.036" | 100 ft (30.5 m) |

Features and Benefits of MI Cable Heaters

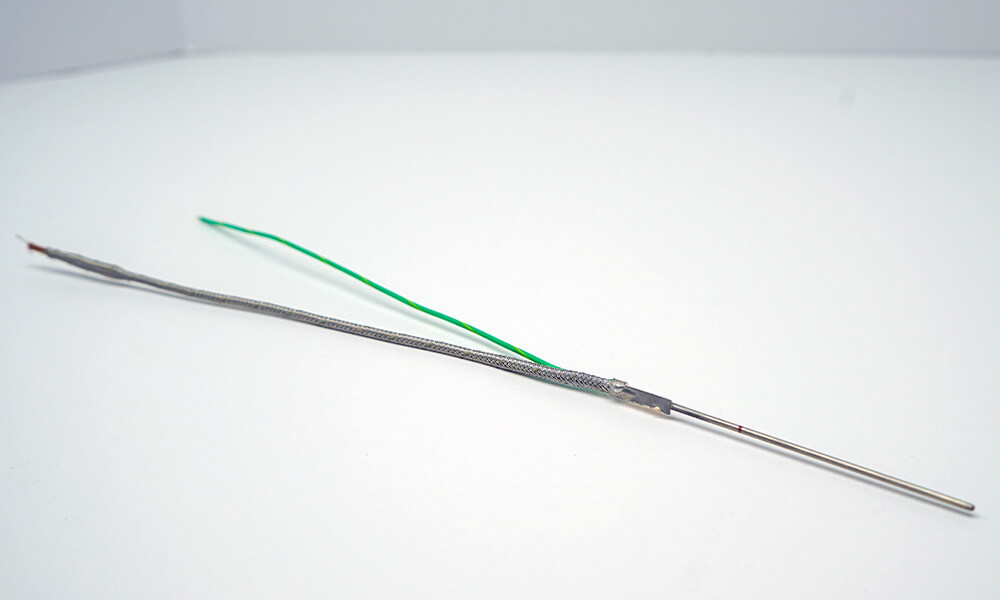

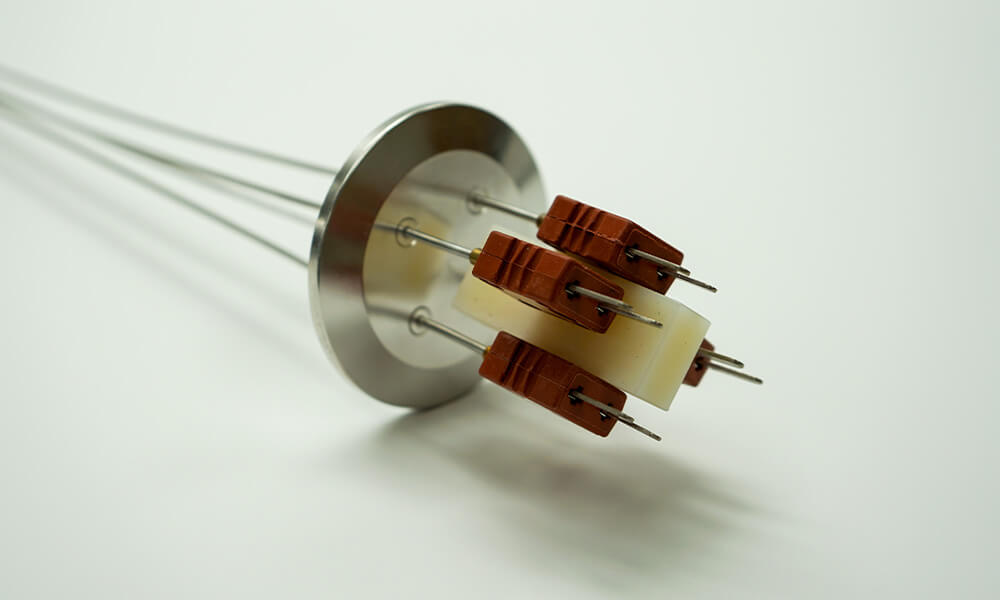

Therm-x Mineral Insulated Cable Heaters begin with the manufacturing of Mineral Insulated (MI) heating cables or elements. The MI heating cables are used as the heating elements for MI Cable Heater, similar to the way as the tubular heating elements are used for process electric heaters, such as immersion, circulation, air duct, and radiation heaters. Individual MI heating cables or elements are fully assembled by using precision tungsten inert gas (TIG) welding of terminals and hot-cold junction. Our MI heating cables features:

- Single or dual resistance wire cores using different materials such as alloys of Nichrome, Cupronickel, and copper, as determined by applications. The MI heating cables can be made with internal thermocouples.

- We use high purity magnesium oxide (Mg) insulation material, 99.4% minimum, for the construction of MI heating cable. The high purity MgO exhibits excellent dielectric strength and allows application voltage at least 600 V, and it is very effective for heat conduction.

- The sheath or tubing materials used for the MI heating cable are typically Incoloy, Inconel, and stainless steel. Other materials can be offered based on the customer requirement of specific applications.

- Wide range of power out or W/Ft for individual MI heating cables, which ultimately allows us to make a cable heater with typical watt density up to 80 W/sq in.

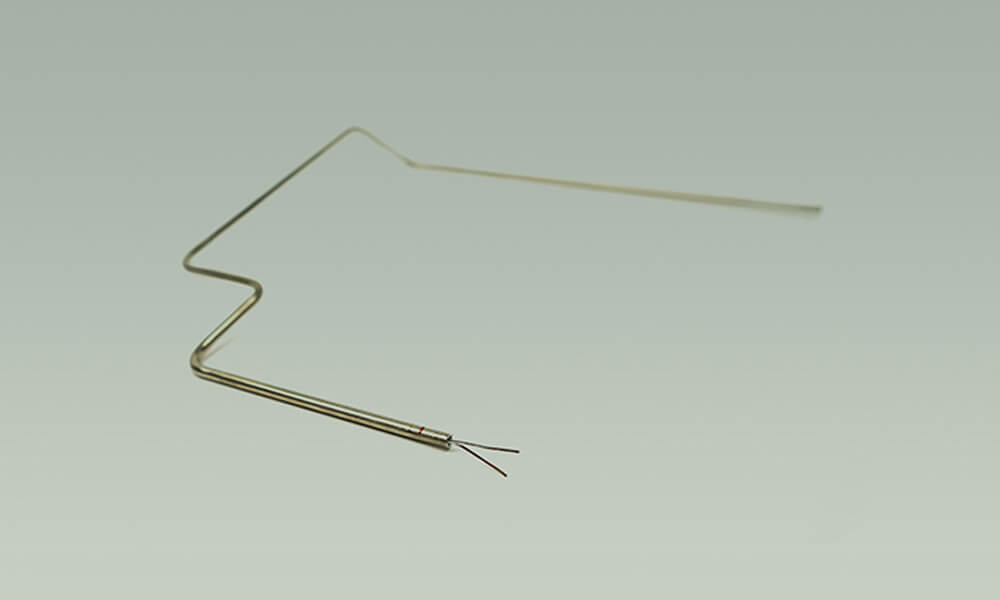

- The typical outer diameter of the MI heating cable is 0.040" to 0.25", which makes the individual MI heating cables highly malleable or flexible and offers great versatility to design MI cable heaters into unlimited shapes and dimensions.

- Versatile design, can be made into any shape, dimensions, and watt density and suitable for a variety of existing customer equipment or process that requires a heating solution.

- Due to its pronounced advantages such as performance, dimensionality, and costs, the MI Cable Heaters can be used to replace other types of electric heaters made with tubular heating elements, such as immersion, circulation, and radiation heaters.

- The heating cables or elements used for the heaters are terminated and spliced using precision TIG welding technology optimized for the diameter and sheath materials.

- Wide range of application voltages, maximum 600 Vac.

- Wide range of watt density, typically 40 to 60W/sq in, and maximum 80 W/sq in.

- High operating temperatures, maximum 1300°F.

- The heaters can be used under corrosive environments if the sheath materials are specified correctly. Incoloy and Inconel sheath materials can withstand a wide range of corrosive substances including liquids of organic acids, bases, and salts. The stainless sheath material can be adopted for mild organic acids and alkalis.

Applications of Therm-x Mineral Insulated Cables

The Therm-x mineral insulated cables are regularly utilized by the following applications

- Heat tracing pipes, fittings, valves, vessels and instruments

- Heating instrumentation for gas analysis

- All types of plastic fabrication equipment

- Packaging and labeling

- Hot stamping - embossing

- Drying - food processing

- Hot knives

- Medical & dental equipment

- Die and mold heating

- Band heaters

- Shoe fabrication

- Heaters combined with thermocouples RTDs or thermistors

- Printing & copy machinery

- Liquid heating

- Duct heating

- Heat guns

- Air heaters

- Resistance coils

Types of Electric Heaters Supported by Therm-x MI Cables

The cable heaters made by Therm-x receive wide applications in industries such as:

Industries

- Semiconductor

- Aerospace

- Power generation & Alternative energy

- Nuclear

- Chemical

- Oil and gas mid-and downstream

- Petrochemical

- Analytical instruments

- Construction

- General engineering

Applications

Demonstrated advantages in electric heating of high temperature, high watt density, high pressure, high radiation, and highly corrosive environments. Specific applications are:

- High temperature heat trace of pipes

- Heated nozzle using coiled MI cable heaters

- Heated plates or platens with embedded MI heaters

- Heating elements for process heaters such as industrial immersion heaters

- Heating elements for duct and air heaters

- Radiation heaters

- Panel heaters

- Drum heaters

- Jacket heaters

- Vessel surface heaters

- Hopper and silo surface heaters

- Vacuum heaters