"Essential Business - We Are Open"

Therm-x of California - Your temperature measurement and control specialists | Therm-x of California Inc.

Integrated systems

email our integrated systems manufacturing specialists

BENEFITS OF USING THERM-X INTEGRATED ENGINEERING SOLUTIONS (IES)

- You will be assigned your own technical team and program manager to guide you through and manage the entire project from start-to-finish.

- Configurable and expandable proprietary solutions as your requirements change and grow.

- Controls solutions that can easily be integrated with your host system.

- Data tracking/logging capabilities and software downloads

- Safety compliant solutions for most industry requirements

- Precise temperature control and monitoring devices at significantly reduced pricing.

- Complete documentation and service manuals, including software instructions and training as needed.

Standards and Certifications

Therm-x designs and builds their integrated control systems in adherence to the following standards and certifications:

- UL® - Underwriter’s Laboratories* (UL 508A)

- FM - Factory Mutual

- NEMA - National Elecrical Manufacturers Association

- NFPA - National Fire Protection Association (NFPA 79)

- AS 9100 - Aerospace*

- UL® - Underwriter’s Laboratories* (UL 508A)

- FM - Factory Mutual

- NEMA - National Elecrical Manufacturers Association

- NFPA - National Fire Protection Association (NFPA 79)

- AS 9100 - Aerospace*

Applications and Market Segments

- Semiconductor Processing Equipment

- Automotive Engineering

- Industrial Process Applications/Refineries

- Food/Beverage Process Equipment

- Chemical Conditioning/Monitoring

- Alternative Energy Industries

- Ovens/Furnaces/Kilns

- Life Sciences & Bio-Pharmeceutical Development

- Packaging/Adhesion markets

- R&D Laboratory requirements

Portable Control Units (PCU)

Therm-x portable control units (PCUs) have been engineered and designed to allow the R&D Process Engineer to have the maximum flexibility when it comes to thermal control and data acquisition in regards to their temperature process parameters and management.

Products:

Features:

- Compact size with mobility and flexibility

- Control and heater fuses

- Serial/ethernet communications available

- Integrated EMO

- Fully self contained unit that can be placed anywhere

- Variable t/c and rtd input available as required

- Control heater on-off switch

- Up to 15 amp rating

Rack Mount Control Panels (RMC)

Therm-x’s rack mount control panels (RMCs) have been engineered and designed to allow the Equipment Engineer to have the maximum flexibility when it comes to thermal control and data acquisition in regards to their temperature process parameters and localized management. Choose from various standard rack sizes or design a custom enclosure with the help of our fabrication engineering department:

- 3u (Standard)

- 4u (Standard)

- 6u (Standard)

- Xu (Non-Standard Size)

Products:

Features:

- Various standard rack mountable sizes available

- Pre-wired for fast start up and connection to host

- Ssr or scr power controllers available

- Integrated EMO

- Variable T/C and RDT input available as required

- Temperature ranges between 0-2400 f

- Fully self contained unit that can be facilitated easily

- Branch circuit protection

- Set -off-on with integrated pilot lights

- 120/240/480 vac single or 3 phase options

- Serial and ethernet communications available

- Safety with all therm-x’s engineered standards

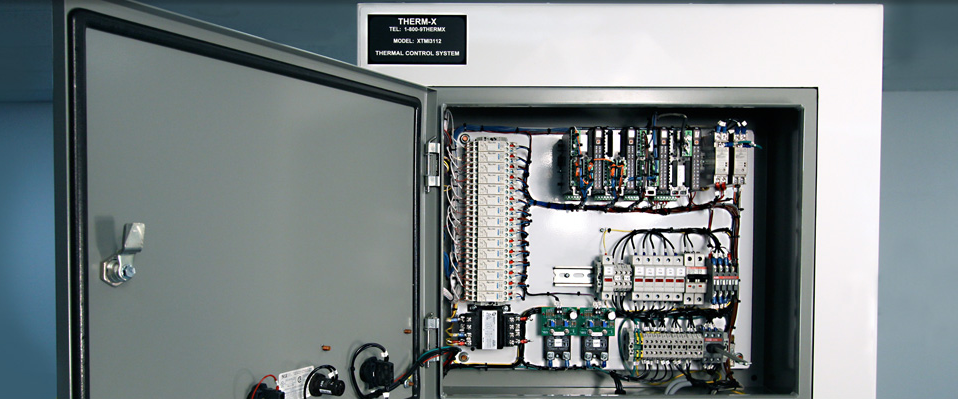

Industrial Control Panels (ICP)

Therm-x’s industrial control panels (ICPs) have been engineered and designed to allow the industrial/field service equipment engineer to have the maximum flexibility when it comes to thermal control and data acquisition in regards to their temperature process parameters and localized management. Choose from the following standard IPC housing options or work with our fabrication engineer department to design a custom enclosure:

- NEMA 1 General Purpose Enclosure

- NEMA 4 Moisture Resistant Enclosure

- NEMA 4x Corrosion Resistant Enclosure

- NEMA 12 Dust Resistant Enclosure

Products:

Features:

- Various standard nema-rated box sizes available

- Hmi and data logging

- Ssr or scr power controllers available

- Integrated EMO

- Variable T/C and RDT input available as required

- Ready for fast installation/start up and connection to host

- Fully self contained unit that can be facilitated/serviced easily

- Design adheres to UL 508A standards

- Branch circuit protection

- Set -off-on with integrated pilot lights

- 120/240/480 VAC single or 3 phase options

- Serial and ethernet communications available

- Safety complaint with all therm-x’s engineered standards

Integrated Process Solutions (IPS)

Therm-x’s integrated process solutions (IPSs) allow our customers to work together with a team of highly technical and experienced Therm-x engineers to design and develop unique temperature management systems that meet their every process requirement. When it comes to thermal control and data acquisition in regards to your temperature process parameters, therm-x’s team works as a valuable extension of your engineering resources. All IPS systems have a complete wiring schematic provided with every unit.

PROCESS SYSTEMS EXPERTISE:

- Environmental conditioning

- Optimized process control and monitoring

- Industrial automation systems

- Control systems for ovens/furnaces/kilns

- Precise temperature management and data logging

- Chemistry balancing and stabilization

- Chemical delivery and reclamation systems

- RF coils and filters

PROCESS SYSTEMS EXPERTISE:

- Air conditioning/Mechanical cooling

- Alarm with silence

- Circuit breaker

- Ground fault detection with relay

- Interlocks

- Two position selector switch

- Software training

- Air flow switch

- Amperage meter

- Certifications (UL 508a)

- Installation, operation and Maintenance manual

- Push button

- Three position selector switch

- Volt meter