Watlow PID EZ-Zone PM Express Controller

Features and Benefits:

Simplified menu

• Fits basic applications with a user-friendly interface supported by two menus and a streamlined list of parameters

• Eliminates complexity often experienced with more advanced PID controllers and unnecessary features

• Reduces training costs and user programming errors

PID auto-tune

• Provides auto-tune for fast, efficient startup

Standard bus communications

• Allows easy product configuration via PC communications protocol and free software

• Saves time, simplifies programming process and improves reliability of controller setup

Factory Mutual (FM) approved over and under limit with auxiliary outputs

• Increases user and equipment safety for over and under-temperature conditions

Agency approvals: UL® listed, CSA, CE, RoHS, W.E.E.E., FM, SEMI F47-0200, Class 1, Div. 2 rating on selected models

• Assures prompt product acceptance

• Reduces end product documentation costs

Front panel removable

• Saves time and labor for replacements and Troubleshooting

P3T armor sealing system

• Complies with NEMA 4X, IP65 specifications

• Allows controller to be cleaned and washed

• Certified UL® 50 independent to NEMA 4X specification

Touch-safe package

• Increases installer and operator safety

• Complies with IP2X requirements

Consistent Termination Labeling (CTL) connection system

• Simplifies switching between products

• Speeds up user’s system documentation

Three-year warranty

• Demonstrates Watlow’s reliability and product support

High-amperage power control output

• Drives 15 ampere resistive loads direct

• Reduces component count

• Saves panel space and simplifies wiring

• Reduces cost of ownership

EZ-ZONE PM Express:

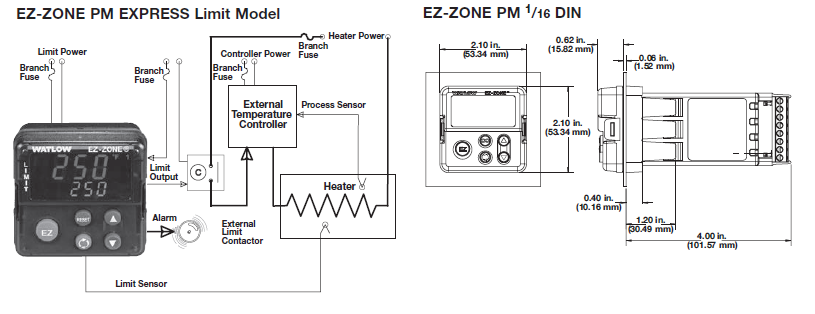

The EZ-ZONE PM Express panel mount controller is an industry-leading PID controller that allows optimal performance utilizing simple control and menu functionality without complex features. It is ideal for basic applications and usage levels.

The EZ-ZONE PM Express is the next generation PID controller to follow the legacy of Watlow’s SERIES 93, SERIES 935 AND SERIES SD controllers that offer easy-to-use features to perform many basic applications. The EZ-ZONE PM Express includes one universal input and an option for up to two outputs and is available in 1/32, 1/16, 1/8 and 1/4 DIN panel mount packages. It can be ordered as a PID process controller or as a dedicated over and under-temperature limit controller.

The EZ-ZONE PM Express is a valuable addition to the EZ-ZONE PM PID controller family which also includes the EZ-ZONE PM integrated controller and the EZ-ZONE PM standard version.

Watlow EZ-Zone PM Express PID Controller

Specifications:

Line Voltage/Power

• 85 to 264VAC, 47 to 63Hz

• 20 to 28VAC, +10/-15%; 50/60Hz, ±5%

• 12 to 40VDC

• 10VA (1/32 and 1/16 DIN) 14VA (1/8 and 1/4 DIN) max. Power consumption

• Data retention upon power failure via non-volatile memory

• Compliant with SEMI F47-0200, Figure R1-1 voltage sag requirements @ 24VAC or higher

Environment

• 0 to 149°F (-18 to 65°C) operating temperature

• -40 to 185°F (-40 to 85°C) storage temperature

• 0 to 90% RH, non-condensing Accuracy

• Calibration accuracy and sensor conformity: ±0.1% of span, ±1°C @ the calibrated ambient temperature and rated line voltage

• Type S: 0.2%

• Type T below -50°C: 0.2%

• Calibration ambient temperature @ 77°F ±5°F (25°C ±3°C)

• Accuracy span: 1000°F (540°C) min.

• Temperature stability: ±0.1°F/°F (±0.1°C/°C) rise in ambient max.

Agency Approvals

• cULus® UL®/EN/CSA C22.2 No 61010-1 Listed, File E185611

• CSA C22.2 No. 24, File 158031

• UL® 50 4X indoor locations, NEMA 4X, IP65 front seal

• cULus® ANSI/ISA 12.12.01-2007, CSA-C22.2 No. 213-1987, Class 1, Div. 2, Groups A, B, C and D, temperature code T4A, File E184390 (optional)

• CE, RoHS by design, W.E.E.E.

Controller

• User selectable heat/cool, on-off, P, PI, PD, PID or alarm action, not valid for limit controllers

• Auto-tune with control algorithm

• Control sampling rates: input = 10Hz, outputs = 10Hz

• Input and output capacity per controller type ordering information

Serial Communications

• Isolated communications

• Standard bus configuration protocol

Wiring Termination—Touch-Safe Terminals

• Input, power and controller output terminals are touch safe, removable, 12 to 22 AWG

Universal Input

• Thermocouple, grounded or ungrounded sensors, greater than 20M$ input impedance, 2k$ source resistance max.

• Non-isolated to switched dc and process output

• RTD 2- or 3-wire, platinum, 100$ @ 0°C calibration to DIN curve (0.00385 $/$/°C)

• Process, 4-20mA @ 100$, or 0-10VDC @ 20k$ input impedance; scalable

Functional Operating Range

Type J: -346 to 2192°F (-210 to 1200°C)

Type K: -454 to 2500°F (-270 to 1371°C)

Type T: -454 to 750°F (-270 to 400°C)

Type E: -454 to 1832°F (-270 to 1000°C)

Type N: -454 to 2372°F (-270 to 1300°C)

Type C: 32 to 4200°F (0 to 2315°C)

Type D: 32 to 4200°F (0 to 2315°C)

Type F: 32 to 2449°F (0 to 1343°C)

Type R: -58 to 3214°F (-50 to 1767°C)

Type S: -58 to 3214°F (-50 to 1767°C)

Type B: 32 to 3300°F (0 to 1816°C)

RTD (DIN): -328 to 1472°F (-200 to 800°C)

Process: -1999 to 9999 units

Output Hardware

• Switched dc = 22 to 32VDC @ 30mA

• Open collector = 30VDC max. @ 100mA max. Current sink

• Solid state relay (SSR), Form A, 0.5A @ 24VAC min., 264VAC max., opto-isolated, without contact suppression

• Electromechanical relay, Form C, 24 to 240VAC or 30VDC max., 5A resistive load, 100,000 cycles at rated load

• Electromechanical relay, Form A, 24 to 240VAC or 30VDC max., 5A resistive load, 100,000 cycles at rated load

• NO-ARC relay, Form A, 24 to 240VAC, 15A @ 122°F (50°C), resistive load, no VDC, 2 million cycles at rated load

• Universal process output: range selectable; 0 to 10VDC ±15mV into a min. 1,000$ load with 2.5mV nominal resolution; 4 to 20mA ±30μA into max. 800$ load with 5μA nominal resolution; temperature stability 100ppm/°C

Operator Interface

• Dual 4 digit, 7 segment LED displays

• Typical display update rate 1Hz

• Advance, infinity (RESET), up and down keys plus an A/M-KEY (not available in 1/32 DIN)

• A/M-KEY automatically programmed as an auto/ manual transfer mode function on PID models.

| Manufacturer | Watlow |

|---|